Nylon is a thermoplastic silky material, generally made from petroleum, that can be melt-processed into fibres, films, or shapes. It was invented in 1927 by DuPont Industries. It is employed in various products, but mostly as a fabric. For example, it is the most used fabric for stocking production.

Image source: https://www.onlinefabricstore.com/makersmill/nylon-fabric-product-guide/

What is Nylon?

Nylon is a synthetic plastic material composed of polyamides of high molecular weight and, normally produced as a fibre. The successful production of a useful fibre by chemical synthesis from compounds readily available from air, water, and coal or petroleum stimulated the expansion of research on polymers, leading to a rapidly proliferating family of synthetics.

Image source: https://www.syrris.com/applications/polymerization/

Development of nylon manufacturing

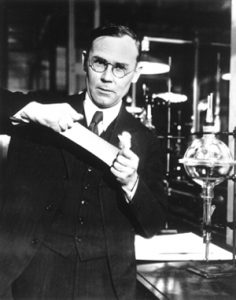

After World War I, DuPont Industries began experimenting with cellulose-based fibres, eventually producing synthetic fibre rayon. DuPont invention of nylon crossed eleven years, extending from the initial research program in polymers in 1927 to its announcement in 1938, shortly before the opening of the 1939 New York World’s Fair. Harvard professor, Wallace Hume Carothers, was chosen to lead the polymer research group. In the spring of 1930, the research team had already synthesized two new polymers. The first one was neoprene, a synthetic rubber employed during World War II. The second one was a white elastic but strong paste that would later become nylon. After these discoveries, Carothers’ team shifted its research to a more practically focused goal of obtaining a chemical combination that would be useful to industrial applications. A cold drawing method was later used by Carothers in 1935 to fully develop nylon. The first example of nylon is nylon 6,6. It had all the wanted properties of elasticity and strength. However, it also required a complicated manufacturing process that would become the foundation of industrial production in the future. DuPont obtained a patent for the polymer in September 1938, and quickly gained the monopoly.

Image source: https://en.wikipedia.org/wiki/Nylon

DuPont nylon project confirmed the importance of chemical engineering. It helped create jobs and promoted the advancement of chemical engineering techniques. It developed a chemical factory that provided 1800 jobs and used the latest technologies, which are still used as a model for chemical plants. The ability to acquire chemists and engineers quickly gave a huge contribution to the realisation of the DuPont nylon project. The first nylon plant was located at Seaford, Delaware, beginning commercial production on December 15, 1939.

How is it made?

Nylon is a polymer, meaning it’s a plastic that contains a molecular structure of a wide number of similar units bonded together. Nylon is a whole family of very similar kinds of materials called polyamides. One reason because there’s a family of nylons is that DuPont patented the first form, so competitors had to come up with alternatives. One more reason is that the different sorts of fibre have different properties and uses. A nylon polymer is produced by two moderately large molecules reaction applying heat around 545°F and pressure from an industrial-strength kettle. When the units combine, they fuse to create a fair larger molecule. This polymer is the most common style of nylon known as nylon-6,6. With an analogous process, other nylon variations are made by reacting to different starting chemicals. This process creates a film of nylon that gets torn into chips. These chips are the staple for all types of ordinary products. However, nylon fabrics are made not from chips but from fibres of nylon, which are strands of plastic yarn. This yarn is formed by melting nylon chips and drawing them through a spinneret, which is a wheel with tiny holes. Fibres of various length and thickness are made by using holes of various sizes and drawing them out at different speeds.

Image source: https://www.dupont.com/

Applications

Nylon fabric was originally marketed as another option for silk stockings. Until the appearance of this fabric, silk was the sole viable material for the kinds of sheer stockings that were then popular with women in the developed world, but silk lacks durability, and it’s notoriously expensive. While the performance of nylon fabric did not quite hold the hype that DuPont gave its origin, it remained a preferred stocking material for the majority of the latter half of the 20th century.

Image source: https://www.divein.com/yoga/yoga-pants/

To the present day, women stockings remain one of the most predominant applications of this material, and it is also applied in tights, yoga pants, and other varieties of form-fitting bottoms for women. This type of material is also commonly employed in sportswear, but it’s inferior to other organic or semi-synthetic fibres during this application. Since its origin, consumers have noted the pronounced inability of this fabric to wick moisture, which makes it a poor choice to be used during physical activity. However, some aspects of this fabric, like its elasticity, are desired in sportswear. even if they’re mainly composed of other fabrics, some sportswear manufacturers include nylon fabric in their textile blends for enhanced elasticity and lightness.

Info sources:

https://pinecrestfabrics.com/fabric-knowledge/why-nylon/

https://en.m.wikipedia.org/wiki/Nylon

https://sewport.com/fabrics-directory/nylon-fabric

https://www.britannica.com/science/nylon